-40%

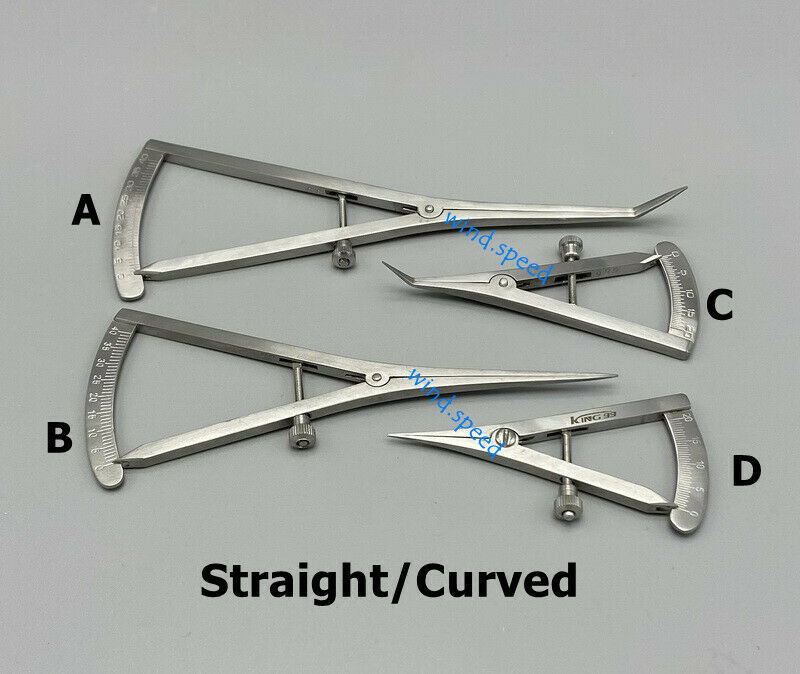

Dental Surgical Instrument Implantology Caliper Implant Gauge 12.5 CM

$ 24.28

- Description

- Size Guide

Description

Dental Surgical Instrument Implantology Caliper Implant Gauge for surgical procedures12.5 CM

.

Material: Stainless Steel

Made in Germany

Instructions for Sterilization and Instrument Care

General requirements for the preparation of medical devices

Please observe the valid legal regulations of your country as well as the hygiene guidelines for

practices and clinics.

■

In particular, please comply with the guidelines regarding the effective inactivation of prions.

The ever-present risk of contamination and infection during treatment must be excluded or

reduced by specific preventive measures. These include:

• Assessment of the risks and dangers in connection with medical practice and definition of

appropriate precautions.

• Schematization and systematization of work routines with the predominant aim of

avoiding contamination and injuries.

• Careful medical history with special regard to patient-induced risks of infection.

■

Not only do used medical devices have to be considered contaminated, but those which are

openly displayed must therefore also be prepared hygienically without exception.

During transport it has to be assured that neither staff nor third parties are at risk. For their

own safety, staff members must wear appropriate protective clothing and protective gloves.

■

Medical devices should not be stored in physiological saline solution as prolonged exposure

may lead to corrosion. The parts must be moistened completely and bubble-free in a bath.

Demineralized water is required under all circumstances for final rinsing after disinfection

to avoid water stains and crystal seeding which may interfere with the subsequent process of

sterilization.

■

As your responsibility includes the sterility of the medical devices used, please bear in mind

that only validated procedures must be used for cleaning, disinfection and sterilization. All

equipment needs to be serviced at regular intervals, and all parameters must be observed

in every cycle. Please observe the shelf-life of the sterile packaging of products (see

manufacturer‘s instructions). Preparation ends with the release for use.

■

Every sterile packaging should display a sterilization indicator and be marked with the date

of sterilization.

■

For medical devices where is not named as manufacturer, please check the specific guidelines

regarding preparation and re-usability in the manufacturer‘s instructions for use.

■

All removable parts must be disassembled for cleaning and disinfection and assembled prior

to sterilization. In case of removable parts, please only clean and disinfect the parts of a single

instrument in a batch.

■

If using an ultrasonic bath, the drills must be placed in a drill organizer.

3

Distinguish between manual and mechanical procedures for preparation, whereby the

mechanical procedure is always to be preferred. The following gives a guide line for mechanical

and manual preparation as well as for sterilization.

Mechanical preparation

Manual pre-cleaning is necessary to provide efficient mechanical cleaning, so that the

mechanical reprocessing of medical devices begins with a manual cleaning step.

1. Manual pre-cleaning:

Coarse contamination such as blood, tissue and bone residue must be removed immediately

after use. To this purpose the instruments are to be removed from the instrument tray and

rinsed under cold running water while removing coarse contamination with a fine, soft nylon

brush. Then the instruments which are to be cleaned mechanically are placed in the cleaning

basket of cleaning and disinfection.

Washer-disinfectors units

1.1 a. Cleaning of medical devices with through-holes, for example, irrigation cannulas or

cooling holes:

Due to the small diameters of the through-holes, medical devices with cooling holes or drills

with internal irrigation make high demands on reprocessing. To ensure safe preparation of such

delicate instruments, these need to be pre-cleaned manually. Hereby it is essential to observe

the following points:

■

Immediately after use, the capillary is to be cleaned from coarse contamination using a Miller

needle and checked for obstructions.

■

Holes are to be rinsed several times with distilled water using a disposable syringe (10 ml).

■

Medical devices may then be cleaned mechanically.

■

Holes are to be rinsed several times with distilled water after mechanical cleaning using a

disposable syringe (10 ml).

1.1 b. Depth Stops for Twist Drills

Disassembly

• Place the tip of the drill on a soft pad (e.g. surgical cloth)

• Now please remove the depth stop manually over the tip of the drill

1.2 Ultrasonic cleaning (optional):

• If the medical devices are heavily soiled or if coarse contamination proves difficult to

remove manually (as described above), pre-cleaning in an ultrasonic bath-is recommended.

• Care should be taken to ensure that the cleaning agent is compatible with the products and

that the exposure times and concentrations recommended by the manufacturer are adhered

to.

• Please also ensure that the liquid levels recommended by the manufacturer of the

ultrasonic bath are adhered to.

4

2. Mechanical cleaning:

Suitable cleaning and disinfecting appliances Washer-disinfectors units are to be used which

are to be validated by the user as part of the established cleaning processes. An example for a

suitable unit is the following one together with appropriate accessories.

Notes on loading

Instrument set is inserted into the cleaning/disinfecting appliance.

■

The instruments to be cleaned, or their disassembled components, are placed in the

destination baskets.

■

The cover of the cleaning basket should be closed.

The instructions of the Washer-disinfectors unit manufacturer are to be followed. The cleaning

and disinfecting agents shall comply. Cleaning and neutralization agents are to be dosed and

used according to the manufacturer‘s guidelines. The water quality recommended for cleaning

(especially for the final rinse phase) is fully demineralized water or water which corresponds

to this level of purity. The recommended cleaning program is the program with thermal

disinfection which operates at the optimum temperature of 45-55°C for the removal of blood, or

any other adequate and validated program.

The program is divided into the following phases:

• Pre-rinse with cold water 4 min.

• Cleaning with alkaline detergent at max.55°C 10 min.

• Neutralization 6 min.

• Intermediate rinse 3 min.

• Disinfection 5 min.

• Drying 30 min.

3. Thermal disinfection:

Thermal disinfection is part of the program and takes into account the value. The latter is a

measure for the reduction of microorganisms in steam disinfection processes.

4. Drying prior to sterilization:

The instruments are dried automatically during the drying cycle in the cleaning and

disinfecting appliance. Clean compressed air can be used to dry drill holes/capillaries. Then the

cleaned and disinfected parts are to be checked again for damage and any corrosion.

Manual preparation

1. Pretreatment (to avoid cross contamination)

Attention: dried contamination may severely impede the reprocessing of medical devices.

One should therefore start pretreatment as early as possible. To prevent drying and for reasons

of personal protection (bactericidal, fungicidal, sporicidal and antiviral effects), medical devices

5

are to be placed in disinfectant solution immediately after use** (shake thoroughly at least three

times). Then, coarse contamination such as blood, tissue and bone residue must be removed.

To this purpose the instruments are to be removed from the instrument tray and all visible

remains of surgery and adhering contamination are to be rinsed off under cold running water

or in a disinfectant solution with a fine, soft brush (nylon) or a clean, soft cloth which is only

used for this purpose. Never use metal brushes or steel wool. Cleaning/disinfection should then

take place within the next 2 hours.

Attention:

At temperatures exceeding 40°C there is a risk of protein coagulation. The optimum operating

temperature for a disinfectant bath is room temperature. This initial disinfection cannot replace

the disinfection step which is carried out after cleaning!

Оptional:

1. Ultrasonic cleaning :

If the medical devices are heavily soiled or if coarse contamination proves difficult to remove

manually as described above), pre-cleaning in an ultrasonic bath-is recommended. Care

should be taken to ensure that the cleaning agent is compatible with the products and that the

exposure times and concentrations recommended by the manufacturer are adhered to. Please

also ensure that the liquid levels recommended by the manufacturer of the ultrasonic bath are

adhered to.

2. Cleaning

• Prior to cleaning the products are to be rinsed with running cold water.

• All removable parts are to be disassembled.

• The water quality recommended for cleaning is distilled water or fully demineralized water.

• Use a suitable cleaning agent such as an alkaline (ingredients for cleaning agents according

to EC Detergents Regulation648/2004: enzymatic, NTA, anionic surfactants).

Attention:

• Cleaning should be carried out at a maximum temperature of 40°C.

• The optimum operating temperature is room temperature.

• The disassembled medical devices are to be placed in a freshly prepared cleaning bath

in accordance with the manufacturer‘s guidelines and then cleaned with an instrument

cleaning brush made of plastic/nylon.

• Medical devices with through-holes, for example, irrigation cannulas or cooling holes

are to be cleaned with a Miller needle and rinsed several times with distilled water using

a disposable syringe (min. 10 ml) at the beginning and end of the exposure time. Ensure

there are no obstructions in the through-holes. After cleaning, the products are to be rinsed

several times with distilled or fully demineralized water.

• After cleaning, the products are to be examined for damage or any signs of corrosion.

• Damaged products are to be replaced.

6

3. Disinfection

For the disinfection of medical devices these are to be placed in a fresh disinfection bath**

(shake thoroughly at least three times).

Attention:

The products must be fully immersed/ wetted by the disinfectant solution. For example, a

suitable disinfectant with bactericidal, fungicidal and antiviral effects (HIV, HBV and HCV).

4. Rinsing and Drying

Following disinfection, the components are to be rinsed thoroughly three times with distilled

water. Drying of the instrument and the drill holes is performed using clean compressed air.

After rinsing and drying, the products are again to be examined for damage or any signs of

corrosion. Damaged products are to be replaced.

Sterilization

• Prior to sterilization, the disassembled medical devices are to be re-assembled.

• The separately cleaned and disinfected medical devices are to be sorted into the provided

sterilizable tray, but can also be sterilized individually.

• The filled trays and/or the individual medical devices are then packed in disposable

sterilization packs (single or double packs) and/or a sterilization container suitable for

steam sterilization.

• Packaging suitable for steam sterilization must comply with the requirements according

to DIN EN ISO 11607 / ANSI/AAMI ST79 / AAMI TIR12:2010, for example, disposable

sterilization packs (single or double packs) temperature resistant up to at least 135°C

(279°F) and sufficient steam permeability, which provide sufficient protection against

mechanical damage, or sterilization containers which need to be maintained according to

the manufacturer‘s instructions.

1. Sterilization

Sterilization is performed in the autoclave 7-10 minutes at 132°C to134°C or for 20 minutes

at 121°C (given are the minimum dwell times, the operating times are longer and canvary

depending on the appliance).

2. Storage

Store the sterilized components at room temperature in a dry and dust-free place.

** Observe information provided by the manufacturer of the instrument disinfection/cleaning

agent with regard to concentration/exposure time and, if given, temperature.

Only disinfectants not containing chlorine, ammonia and aldehydes and with proven efficacy

against HBV, HCV and HIV may be used, and which comply with the respective current

national regulations on disinfectants (i.e. FDA approval, DDGHM (2002)/VAH (2011)-listed, CE

label, etc.).

Disinfection should be performed using aldehyde-free agents due to the protein-binding

properties of aldehyde-containing disinfectants.

7

[1.] DIN EN ISO 17664 Sterilization of medical devices– Information to be provided by the

manufacturer for the preparation of re-sterilizable medical devices (ISO17664:2004); German

version EN ISO 17664:2004

[2.] RKI Guideline 2001: Hygiene requirements for the preparation of medical devices

(Bundesgesundheitsblatt44: 1115-1126) (German Federal Health Gazette)

[3.] Guidelines of the DGKH (German Association for Hospital Hygiene), DGSV (German

Association for Sterile Services) and AKI (Working party instrument preparation) for the

validation and routine monitoring of mechanical cleaning and thermal disinfection processes

for medical devices and the principles of equipment selection, 3rdedition 2008.

[4.] Draft Guidance for Industry and FDA Staff/Processing/Reprocessing Medical Devices in

Health Care Settings: Validation Methods and Labeling 2nd May 2011.

[5.] ANSI/AAMI TIR12 September 2010 Designing, testing, and labeling reusable medical

devices for reprocessing in health care facilities: A guide for medical device manufacturers.

[6.] DIN EN ISO 15883-1 (2006-09) Cleaning and disinfection appliances - Part 1: General

requirements,

Definitions and test methods (15883-1:2006); German version EN ISO 15883-1:2006

Trays/kits have to be conditioned after each use. Please disassemble them according to the

following instructions:

■

Please remove all products from the tray/kit for conditioning (cleaning/disinfection). Now

disassemble the tray/kit completely into its individual components.

■

Remove the base plate and the accessory box, if present, from the tray or the kit.

■

Remove the aluminum insert for separate cleaning.

■

Reassemble the cleaned and disinfected tray/kit for maintenance and assembly. Do not use

instrument oil or damaged trays.

■

Place the separately cleaned and disinfected instruments back into the tray (preparation for

sterilization).

■

Please pack the trays in disposable sterilization packs (single or double packs) and/or

sterilization containers that conform to the requirements.

■

Sterilization is carried out as described previously.

IMPORTANT!

• All medical devices which are supplied non-sterile must be sterilized before being used on

patients for the first time.

• All re-usable medical devices must be prepared and sterilized after each use in accordance

with the described procedures. If a different procedure is used, this must be validated by

the respective practice or hospital.

8

• Not all medical devices can be re-used repeatedly. Products which are not suitable for

steam sterilization due to their material composition must be subjected to disinfection

prior to use. Information on whether a product is re-usable, needs to be disassembled for

preparation, or can be sterilized in an autoclave.

Shipping Information:

The average shipping times for our orders are as follows (standard shipping):

Worldwide: 7-21 Business Days

If for some reason your order has not arrived within 40 Days, please get in contact with us so we could help you.

(After the shipping started, the order will be monitored and the track of the item will be posted on eBay

Payment:

Payment can only be made by PayPal via eBay. To ensure your purchase is protected, it will only be delivered to your registered PayPal address (Due to safety reason we do not allow change address through email). Payment for Buy It Now purchases must be made immediately. Once your payment has been received we will send you a confirmation email.

If your item needs to be shipped to an alternative address, please update the address on PayPal before placing your order. We will only ship to your registered PayPal address.

Return Policy:

We want you to be completely happy! If for any reason you are not happy with your purchase, we will gladly accept returns. You can send back a goods within 60 Days. Return shipping will be paid by Buyer.

Returned items should be in unused, not damaged or worn conditions. Returned items need to be in original packaging.

SERVICE/FEEDBACK

Questions:

Were here for you!

We are proud to offer quality service and we want your transaction to go perfectly. Take advantage of our customer service representatives who are here to help you, contact us on eBay. Thank you for your interest and we hope to do business with you! We would be thankful if You could leave good response about us.

Thank you for your interest and we hope to do business with you!